Reduce production costs, encourage high productivity

Software OTRS (Operation Time Research Software) 10,000+ users in 31 countries

OTRS 10 (Operation Time Research Software)

Time-Motion Analysis Software to optimize productivity, achieve cost efficiency, and transfer Skill

Productivity and Efficiency of Production Costs Be an obstacle in your business?

Whether your business is facing low productivity challenges, inefficient production costs, as well Challenges in Transferring Science and Work Skills? The three things below are frequent common problems occurs in business and industry today.

How to optimize productivity at my workplace?

I feel my workplace is not productive but I don't know how to analyze productivity and How to start?

How to achieve the efficiency of analyzing work patterns?

We conduct time study analysis even though the method depends on workers. It took a lot of time, Data collected fluctuating, and the output is not as expected.

How to transfer knowledge and skills to other workers?

Training workers constrained the difficulty of transferring knowledge and reliable skills to other workers and new workers making it difficult to create multi-skill workers.

OTRS 10 Software: Time-Motion Study Software to Overcome Productivity Problems

OTRS Software (Operation Time Research Software) is sophisticated software for time-motion purposes Study, which is a study to analyze work processes, identify ineffective work patterns And efficient, the aim of which is to optimize work productivity and achieve production efficiency.

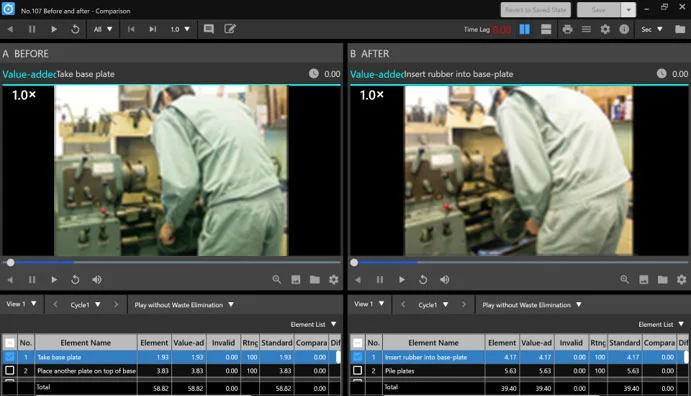

Elimination of 'Waste', Stand the Process

OTRS software makes it easy for you to compare two different videos (for example: videos from working conditions Currently with videos from experienced workers), thus facilitating the identification process 'Waste'. Playback features, reverse playback, frame by frame playback OTRS helps eliminate Work patterns that are not practical, not important, and inefficient quickly and easily. This far more effective than documents or written explanations.

Video Record, Find Efficiency

OTRS videos are easily shared and seen by workers so they can quickly find patterns Work that is not practical, not important, and irregular. Workers can see examples of patterns ideal work and how it influences time management. With this, OTRS brought substantial differences in worker productivity and time efficiency.

5 Reasons Why Choose OTRS Software 10

Here are 5 reasons why OTRS is the right and best solution for optimizing productivity workers, achieve efficiency, and facilitate transfer skills.

OTRS support & service

USB Key Damage Guarantee*

If the Security Key (USB) is damaged, PT. MC Technos Indonesia will replace it with a new one. FREE!

*The warranty does not apply to the case of loss. If the USB Key is lost is not the responsibility of PT. MC Technos Indonesia.

DVD Installer Damage Guarantee*

If the DVD installer is damaged or lost, PT. MC Technos Indonesia will replace it with the latest version. FREE!

*Version adjusts available stock conditions.

Help Desk Service*

Help Desk Service PT. MC Technos Indonesia is available every working day, Monday -Friday, from 08:00 - 16:30 WIB to help customers with questions about the operation and use of OTRS.

Onsite Service*

ONSITE SERVICE PT. MC Technos Indonesia provides experienced technicians who come directly to the location You are to help with the installation, support, and maintenance of the OTRS system.

*(FREE for the Jabodetabek area).Create an effective and efficient new work process with OTRS

OTRS software facilitates work process analysis through time-motion methods, which identify time and Effective movements in doing a job.

4 Steps for OTRS to Increase Productivity

- Identification and visualization of work techniques that are less effective.

- Compare the performance of experienced workers with beginner workers.

- Use a simulation to evaluate the potential changes in the work process.

- Perform a simulation to increase overall operational efficiency.

3 Specific Methods of Increasing Productivity

visualization

Reduction

Simulation

Operational efficiency

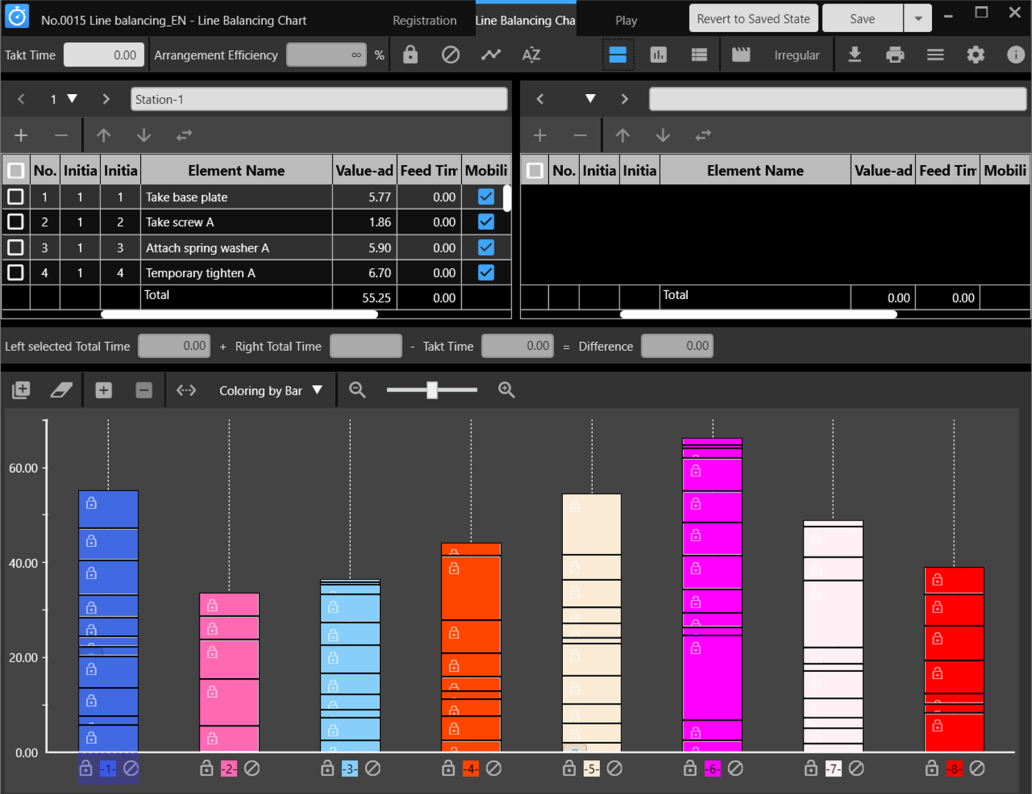

Key Functions OTRS to optimize operational performance

Develop a better work technique

Video comparison

Comparing two videos easily, between skilled workers and beginners, equipped with various Playback features to identify ineffective work methods quickly.

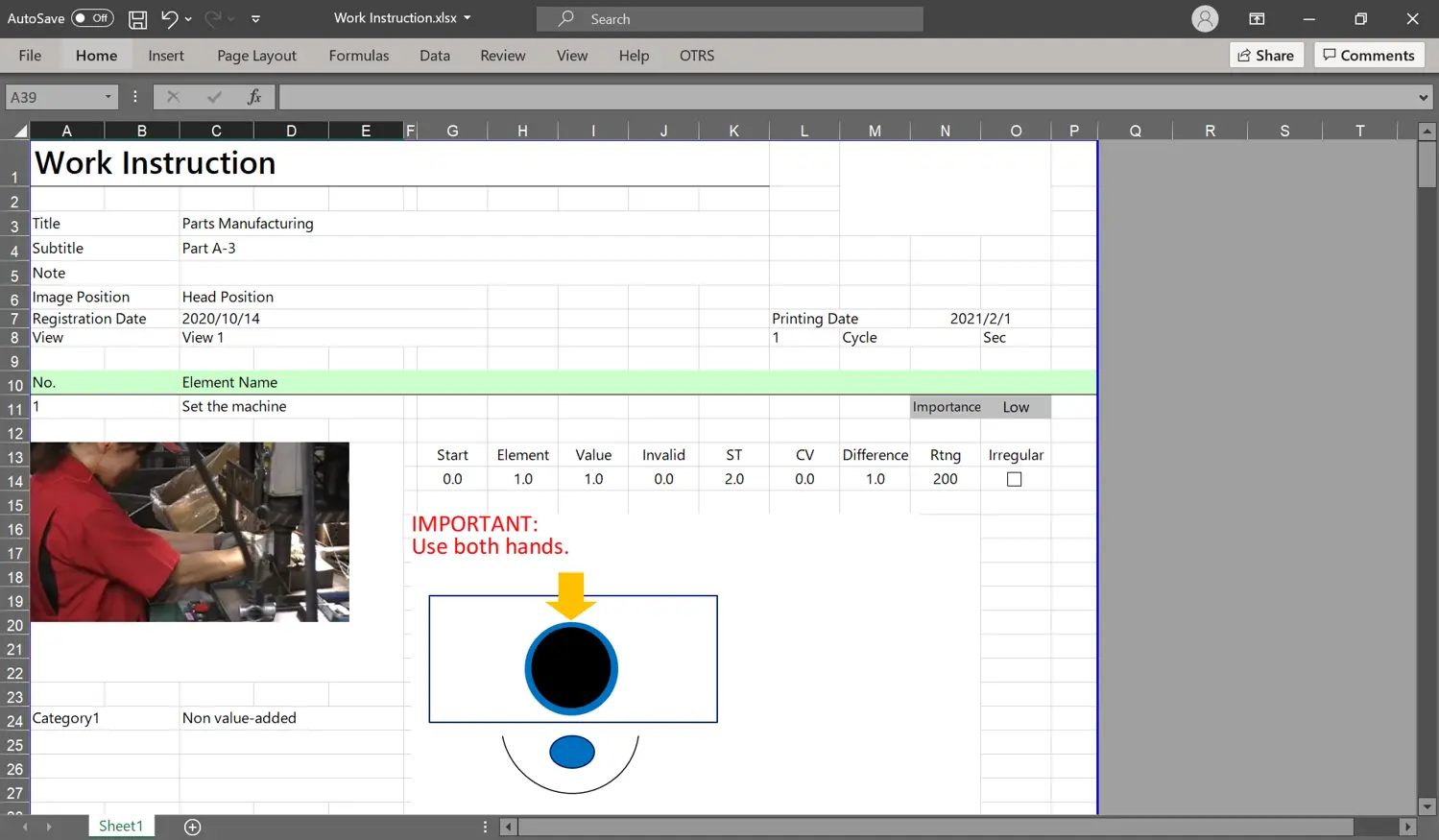

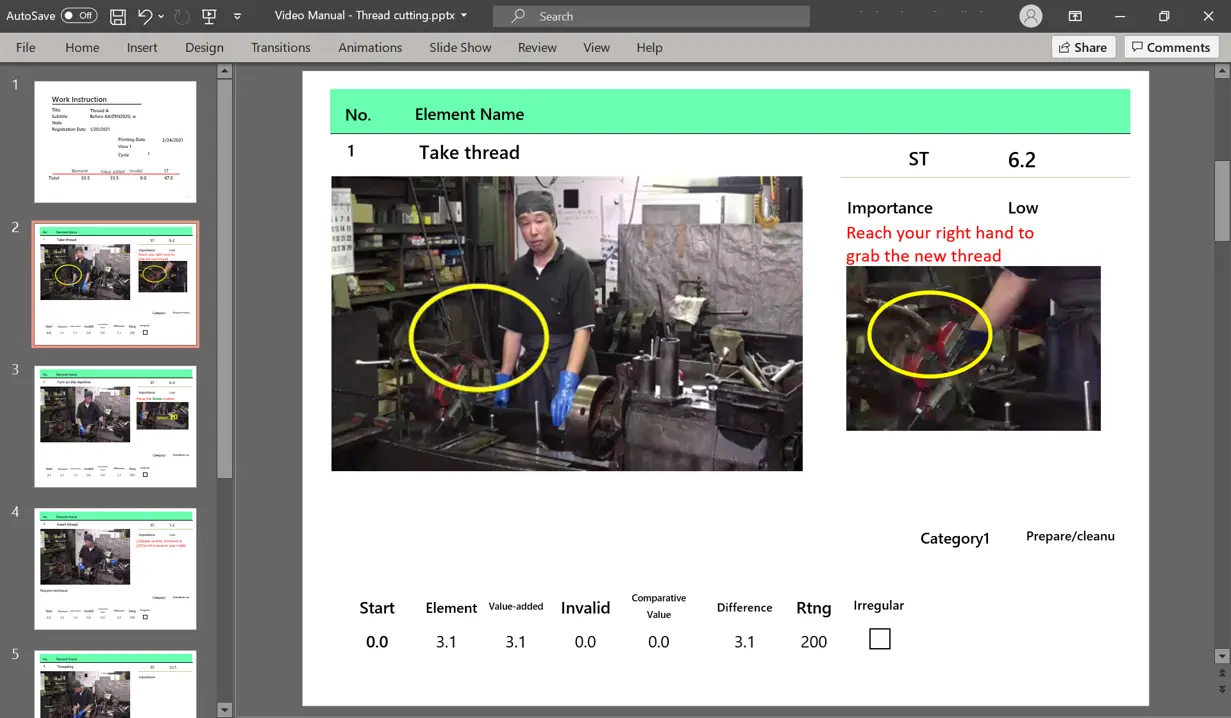

Manual Video

Video Analysis results can be easily used as a video manual for other workers. Kaizen for employees Can always be done quickly!

Make video guides for employee training

Make a guide

OTRS simplifies employee training process. Periodic analysis and training for skill improvement Employees become easier, faster, and more effective.

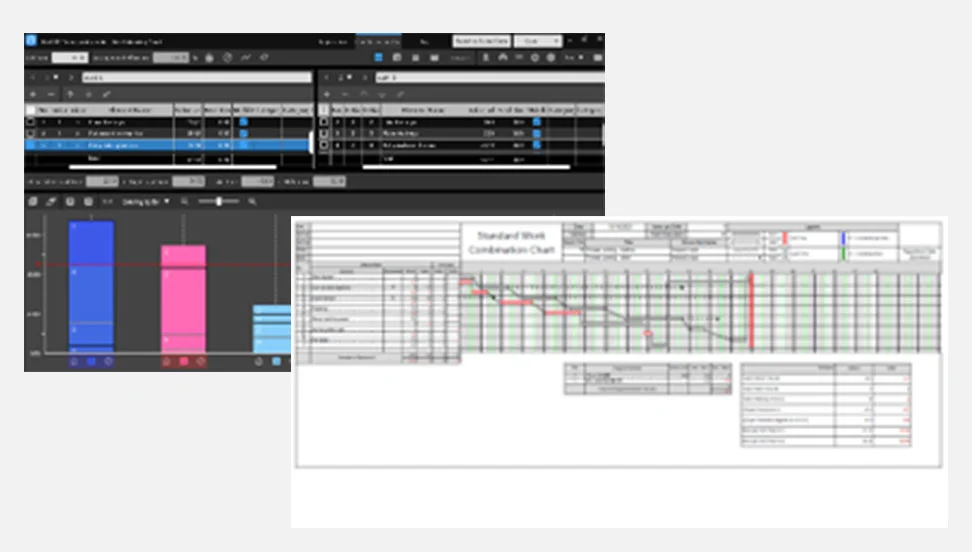

For standardized work instructions

Video analysis results can be added subtitles to clarify the information conveyed through Video. Work instructions become clearer and more standardized.

Delete repeated waste, add insight

Job Analysis

Subjective instructions and improvisation are not enough. Identification of waste and determine goals in a way objective to achieve an increase.

Output Video

Form of knowledge foundation by making post-analysis videos that are equipped with additional text.

6 Reliable OTRS features

6 Reliable OTRS features allow precision and efficient analysis in understanding and improving the process work through time-motion analysis software.

Do enough analysis by clicking the mouse

OTRS is easy to operate without requiring special understanding. Enough mouse your computer for Navigating a variety of features, allows fast and accurate analysis to identify variations your work.

Compare two videos, delete waste

Compare the two videos that have been analyzed to check, verify, and correct issues work easily.General playback, reverse playback, and playback frame-by-frame features are increasingly Facilitate the elimination of inefficient or problematic patterns.

Optimize the process by rearranging the elements

Easy to rearrange each element of each cycle to find the most optimal combination. Video results can be exported and used as data analysis according to your needs.

Combine the results of the analysis and arrange the report easily.

Use a work composition simulation with a rating feature that allows performance appraisal effective and fair from experienced workers. The simulation results can be exported to the table for Get a better understanding based on a variety of combinations.

Show the results of the analysis in the report format you want

Use OTRS analysis results to create Excel® documents according to your needs.Document can used to improve work standards or make manuals and SOPs.

One click to create a video guide from the analysis results.

Use as video material via PowerPoint® for education, training, and development Skills.Fast, accurate, and easy to understand.

Request Demo/Trial

PT. MC Technos Indonesia as the official distributor of OTRS 10 software offers free software trial and support.What do our customers say about OTRS?

What do our customers have successfully optimized productivity, streamline production costs, and Facilitate transfer skills thanks to OTRS software.

"OTRS increases our productivity to 25%"

Toyota Boshoku Corporation

"Thanks to OTRS we save millions of yen!"

Marugo Rubber Industries, Ltd.

"OTRS makes it easy for us to transfer knowledge and skills from experienced workers to workers other!"

Kubota Corporation

"With OTRS, an analysis of procedures that usually takes 2-3 days, is now only 1-2 hours!"

Takenaka Corporation

"OTRS really motivates our workers!"

SUNAQUA TOTO LTD.

"OTRS and VSM are the best collaboration!"

Yachiyo Industry Co., Ltd.

Download the OTRS guide brochure

Learn more about OTRS, download our OTRS brochure now.How effective is OTRS?

How effective is OTRS in optimizing performance? Let's look at the effectiveness of OTRS in the following numbers

Reduce time for work analysis as much as

"Previously, we measure all our work using a stopwatch, but we have to repeat the process it repeatedly to get the correct measurement to be analyzed. But, with OTRS and The interface is easy to use*, we can speed up video playback and see it frame by frame, which makes video analysis into a simple and fast process. "

Production output increases from

per day

"Thanks to the OTRS and the simulation feature of the work process*, we can find ways to improve the way it works We, complete the task easily without creating bottlenecks. The simulation tool allows us rearrange our operations, even we can find a new approach to complete the task. This drastically increases the amount of work we can complete in one day. "

Training clock decreases

"Usually we hold OJT (on the job training)*(1) with staff before they start working in line assembly. But with OTRS, we do staff training with the comparison method, which is to record the way the new staff work and compare it by working experienced staff*(2). The result is time needed for staff training effectively decreases by 50%.

Our location

PT. MC TECHNOS INDONESIA (official distributor)

Kawasan Industri MM2100 (Mitsubishi Logistics Indonesia)

Jl. Jawa Blok G No.1, Gandamekar, Cikarang Barat, Bekasi, Jawa Barat, 17530

+62-21-8998-3916 ~ 3920

info@mctechnos.co.id

Request Demo/Free Trial OTRS

Try free OTRS for 30 days. Fill in the following contact form and our team will immediately contact you.